End To End Solutions

END TO END SOLUTIONS

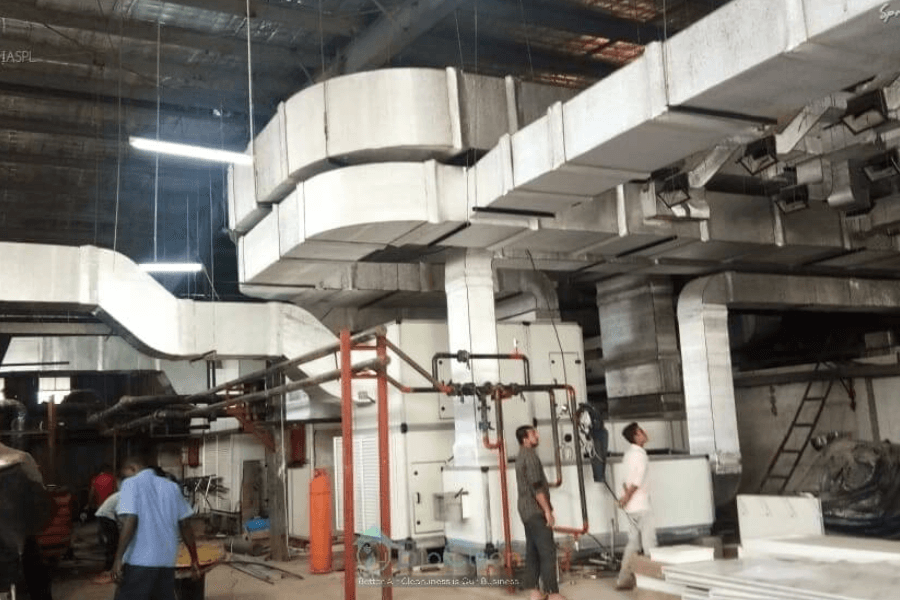

Bio Clean handle Projects from Thought to Finish, THINK PHARMA – WE DO, We are a Turnkey Solutions Provider with an Engineering Consultancy at its core of services which provides paced & sequenced execution that transforms your facility. The facility is designed to support the Manufacturing process with respect to sustainability, output, compliance, regulations, and market-ready supply chain facility. A detailed plan of action including Project Execution Schedule and Validation Master Plan is put in place prior to Execution so to have right visibility in Supply Chain as well as site preparedness.

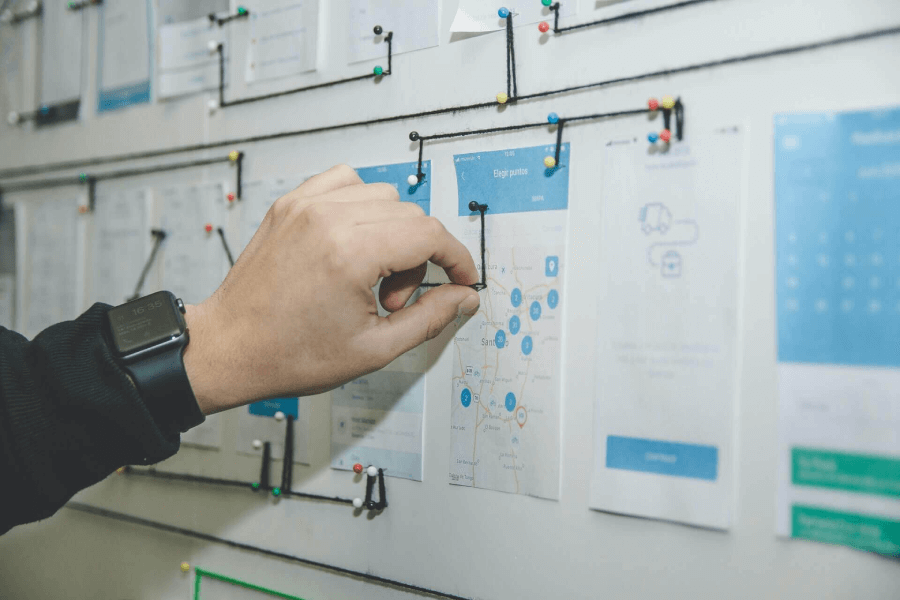

We realize that our clients have a lot riding on their projects. Our deep involvement at every stage of a project, and total commitment to quality and on-time delivery give our clients a sense of comfort and assurance. Constant communication with clients, PMCs and other associated agencies forms a part of our approach to project management. Similarly, we pay attention to the prioritization of issues and to maintaining accurate documentation at every stage of the project. We believe in giving clients a hassle-free experience during every project, topped up by committed after-sales support.

Bio Clean uses a ‘Staged’ approach to Execute and Design Projects which allows the Delivery of Controlled and Cost Effective Solutions to Clients. At the end of each stage, the project goes through a “gate” where it is challenged and a decision on whether to proceed is made. This staged approach allows Bio Clean to either provide Clients the full Project Package or Individual Project stages as required, giving the client flexibility and knowledge of what services are being provided.

Where stages are combined or omitted, the activities and deliverables are reviewed to ensure all essential tasks are still incorporated into the project. This methodology applies the concept of “front-end loading” which refers to an increased extent of effort expended at the start of a project to initiate, define and scope the project. Projects which have good front-end loading and use a disciplined Stage Gate Process achieve Quality, Schedule, Cost and Risk Management Advantages.

We do an Initial Engineering Concept Design, starting with your product and market requirements, documented in a User Requirements Specification. Our Pharmaceutical engineers help you in equipment selection, understand the advantages and disadvantages of certain technologies and, based on our industry experience, we can therefore advise on the best options. We will work closely with your team to develop the most appropriate facility design solution based on your process requirements while also achieving GMP Compliance. Our Complete GMP compliance, Engineering and Validation service will ensure a high level of confidence that the correct GMP Target / Standard is set, Engineers design it right and Our Validation engineers ensure that the project quality control is done properly and GMP certification is assured.

Related Services

Project Management & Control

Faster Corrective Action

QA and Check

Project Documentation

Supply Chains

Procurement from Reputated Makes.

Delivering Goods at Right Time.

Inst, Commissioning & Validations

Mobilization of Expert Staff

Daily Installation progress

Monitoring, Testing & Validation