Services

A Complete Project

Solutions

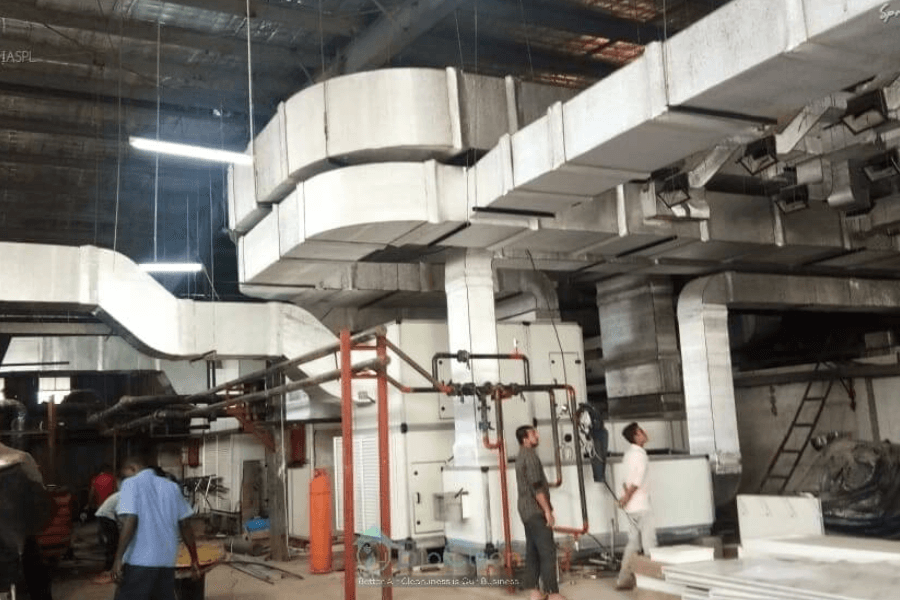

Bio Clean handle Projects from Thought to Finish, THINK PHARMA – WE DO, We are a Turnkey Solutions Provider with an Engineering Consultancy at its core of services which provides paced & sequenced execution that transforms your facility. The facility is designed to support the Manufacturing process with respect to sustainability, output, compliance, regulations, and market-ready supply chain facility. A detailed plan of action including Project Execution Schedule and Validation Master Plan is put in place prior to Execution so to have right visibility in Supply Chain as well as site preparedness.

GMP facility design for Cleanrooms in Pharma, Food or Electronics Industries requires very specific knowledge and experience. We understand that both the regulatory and workflow requirements are critical to success when building or renovating facilities. A common expression is that you need to ‘build-in‘ quality. This means that the quality of a product should be built-in at every stage of the manufacturing lifecycle instead of solely relying on Quality Control tests at the very end of the process.

One step before building-in quality is ‘designing-in‘ quality. This is often covered in the Initial Planning, Research, Development and Scale up of a Product but also includes the preliminary GMP Facility Design.

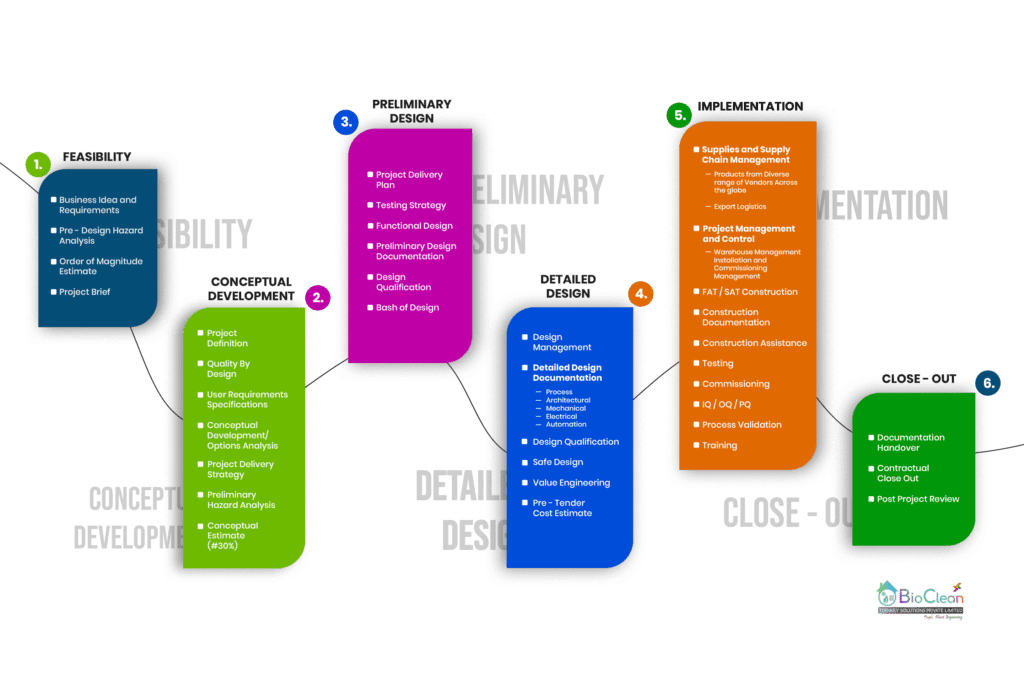

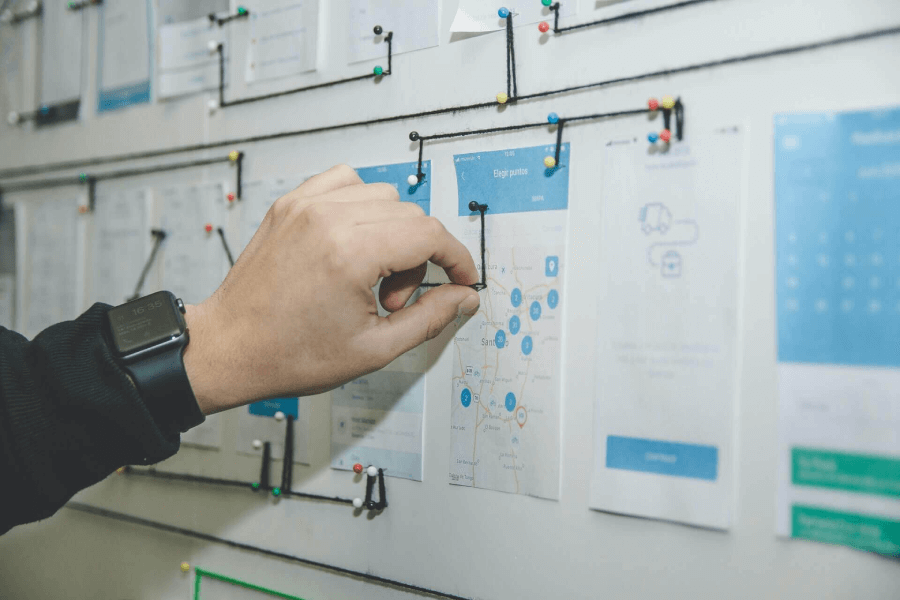

Our Engineering Process

The Six Stages of a Bio Clean Engineering and Design process

Services Offered

End To End Solutions

Facility Design & Machine Selection.

Project Scheduling & Execution

Supply Chains

Procurement from Reputated Makes.

Delivering Goods at Right Time.

Project Management & Control

Faster Corrective Action

QA and Check

Project Documentation

Inst, Commissioning & Validations

Mobilization of Expert Staff

Daily Installation progress

Monitoring, Testing & Validation